Advantages of Wang Resin in Peptide Synthesis

Wang resin is the most widely used resin for solid-phase peptide synthesis. It is compatible with Fmoc chemistry and enables the synthesis of peptides, which are crucial in various scientific and medical applications. By using Wang resin, laboratories and research facilities can achieve their objectives more efficiently and effectively. The distinct characteristics of Wang resin make it a preferred choice in peptide synthesis. Its chemical structure allows for a streamlined attachment of amino acids, which is essential for fast and reliable synthesis. Notably, Wang resin excels in conditions where other resins might falter, making it especially valuable in complex peptide formations.

At AltaBioscience, we supply Wang resins preloaded with all 20 amino acids, including Fmoc Ala Wang resin and Fmoc Val Wang resin. After mild cleavage with TFA, the peptide products have C-terminal acids, ensuring clean and precise synthesis. Explore our full range of preloaded Wang resin.

Wang resin – Key properties and features

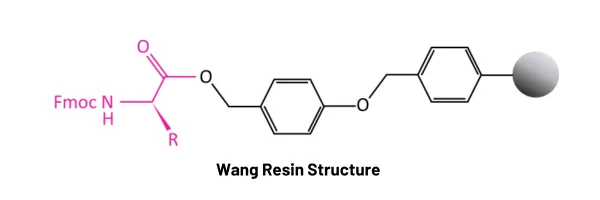

Chemical Structure of the Wang solid support

Wang resin is a polystyrene-based solid support that is cross-linked with divinylbenzene. This cross-linking is essential to lend it both stability and a degree of rigidity. As a result, it provides the necessary mechanical strength and prevents disintegration during the synthesis process. Its defining feature, however, is the presence of an ester linkage, which is attached to the phenolic hydroxyl group of the polystyrene. This linkage is the site where the first amino acid of the peptide chain is anchored. The stability of this ester bond is carefully balanced. It is robust enough to remain intact during the sequential addition of amino acids, yet it can be cleaved under mildly acidic conditions to release the finished peptide. This design of Wang resin makes it highly efficient for synthesising peptides with a wide range of complexities and lengths, offering a level of control and versatility that is invaluable in peptide synthesis.

Resin crosslinking density

The resin must be able to swell in solvents to allow the reactants to diffuse into the resin and have sufficient space to react. The crosslinking density, typically determined by the percentage of divinylbenzene (DVB) used, can affect this. The higher the percentage of cross linkage with DVB, the lower the swelling is in a specific solvent. Lower crosslinking (1% DVB) results in better swelling and reagent accessibility, potentially leading to more efficient synthesis. However, if required, higher crosslinking (2-5% DVB) can be used to improve mechanical stability.

Particle size

The particle size of Wang resin significantly affects its performance in solid-phase peptide synthesis (SPPS). Smaller resin particles have a higher surface area-to-volume ratio, which can improve swelling and enhance solvent penetration. Smaller particle size can also improve the diffusion of reagents into the resin beads. This can result in faster and more complete coupling reactions, and is especially beneficial for synthesising longer peptides or those with sterically hindered residues. However, on the practical side, smaller particle size may increase in the filtration times and may present challenges for automated systems due to handling and flow issues, requiring careful optimisation. For optimal peptide synthesis, common resin sizes are 100-200 mesh and 200-400 mesh.

Resin loading

Resin loading is defined as the number of reactive sites per gram of resin. High loading values result in higher efficiency, but lower loading can help with the synthesis of more difficult peptides in order to reduce intra and intermolecular interactions.

Advantages of Wang resins

Wang resin offers several advantages including:

- Compatibility with a wide range of building blocks and solvents used in SPPS and Fmoc chemistry: Wang resins can be used with a wide range of Fmoc amino acids, including non-standard amino acids with unique side chains, post-translational modifications (phosphorylation/glycosylation), and those requiring special protection/deprotection strategies. Common solvents used with the resin include N,N-Dimethylformamide (DMF), Dichloromethane (DCM), and N-Methyl-2-pyrrolidone (NMP).

- Easy cleavage of the synthesised peptide: The mild acidic conditions used for cleaving peptides from Wang resin (typically using trifluoroacetic acid) are gentle enough to preserve the integrity of the peptide. In particular, sensitive modifications introduced during synthesis are less likely to be degraded during cleavage. In addition, they are excellent for synthesising linear peptides due to the straightforward cleavage mechanism that releases the peptide with a free C-terminal carboxyl group. This makes it ideal for applications where a free C-terminus is required, such as in many bioactive peptides and therapeutic agents.

- Suitable for both manual and automated synthesis. Its adaptability to different synthesis methods makes it a convenient choice for various laboratory environments and scales of production.

- Availability of Fmoc amino acid preloaded Wang resins: The first amino acid coupling with the Wang resin is a crucial step that must be optimised to ensure the subsequent successful synthesis of the peptide. It is achieved by attaching the amino acid to Wang resin via its carboxyl group, forming an ester bond with the hydroxyl group of the Wang linker. This is usually done using standard coupling reagents like DCC (dicyclohexylcarbodiimide) or DIC (diisopropylcarbodiimide) in the presence of a catalyst like DMAP (4-dimethylaminopyridine). However, challenges may arise when loading the first amino acid to the resin. The reaction with the resin may be incomplete, the first amino acid may racemise, or subsequent reactions may generate impurities if the reacted sites are left unblocked. Because of these difficulties, it is recommended to use already preloaded Wang resins, such as the ones provided by AltaBioscience.

High quality Wang resins ready to ship

Our preloaded Wang resins and peptide synthesis reagents are competitively priced and ready to ship from our ISO 9001-certified UK-based laboratory. All products undergo rigorous quality control to ensure they meet and exceed industry standards, supplying clients with the highest quality products for their peptide synthesis requirements.