Design considerations in the synthesis of peptides

In this article, we detail some of the design considerations we use in peptide synthesis.

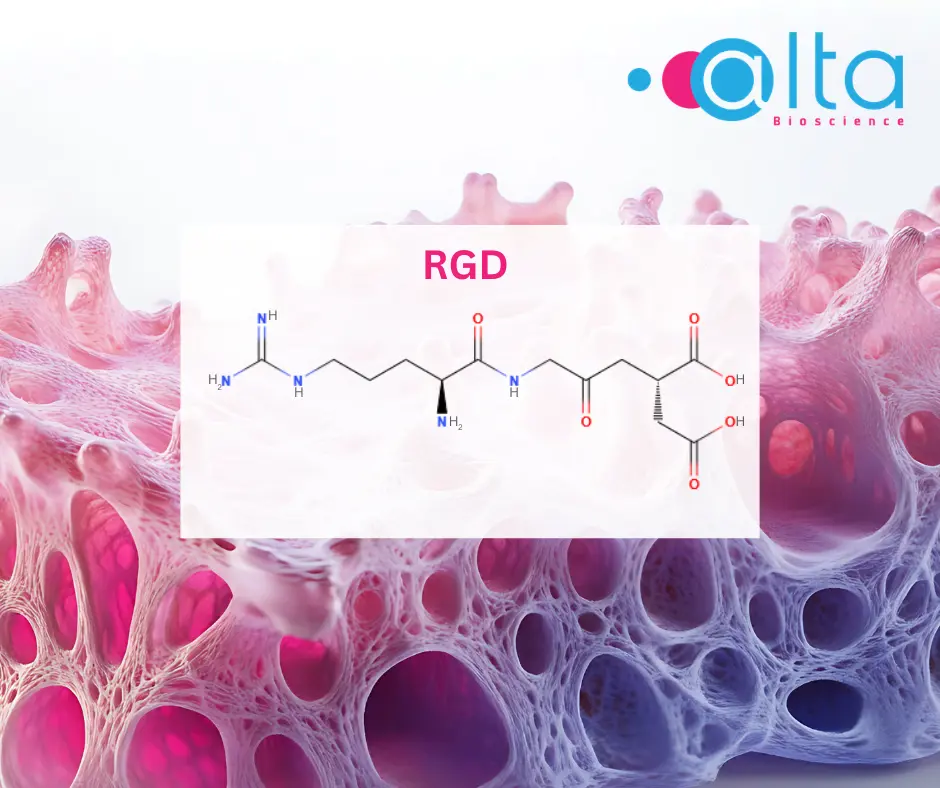

Design and structure of peptides

We can incorporate all the standard amino acids and other moieties from the extensive range of building blocks available. We only use high-quality reagents sourced from reputable suppliers to ensure our customers receive products of high quality. Synthetic difficulty is sequence dependent; however, our peptide chemists, using their experience in synthesis optimisation, have increased our success rate of synthesising difficult peptides, e.g. amyloid peptides and proteins.

Length of peptides

Our synthetic methods are routinely used to produce peptides and proteins in the range of 3-70 amino acids. However, we also have experience in successfully making peptides of over 80 amino acids. The longer the peptide, the greater the number of impurities to be removed from the target sequence, thereby affecting the absolute purity of the product. A longer peptide will also have a higher chance of containing a sequence region that is difficult to synthesise. However, with many years of experience, AltaBioscience has overcome such challenging peptides. We can advise on any possible concerns regarding the viability of a particular synthesis.

Synthesis Options and Applications

• Peptide antigens for antibody generation.

Synthesis of peptide to target epitope, incorporation of posttranslational modifications into a sequence.

•Affinity columns for antibody purification.

Fast, robust, effective peptide product for the purification of peptide and protein antibodies from serum.

• Linear peptides. Syntheses from tri-peptides up to 90+ amino acids.

• Branched peptides. Branching from a C-terminal poly-lysine core or mid-sequence branching. This would enable you to have individual peptides on different branches.

• Modified amino acid peptides. Incorporation of D-amino acids, phosphorylated amino acids, amino acid analogues, spacers.

• Tags. Biotinylated, fatty acids, pegylation, farnysyl, photolabile linkers, maleimide.

• Fluorescent and Dye Labelled Peptides. Peptides with fluorescent or other dye labels provide useful tools for monitoring biological interactions, receptor-ligand binding, protein structures and enzyme activity. Read more about fluorescent peptides.

• Isotopically labelled peptides. For use in quantitative mass spectrometry. Peptides are synthesised incorporating amino acids enriched with the stable isotopes 13C and 15N.

• Cyclic peptides. Cyclisation of a peptide provides the benefit of constructing a constrained shaped peptide.

• Stapled peptides. Provide stable helical structures, aiding protease resistance and cell-permeability and increasing binding affinity to target.

• Histone peptide synthesis and microarrays.

• Custom microarray peptides. For investigation of protein-peptide interactions using your own peptide sequences.

• Peptide conjugation.

o Peptide – protein conjugation KLH, BSA, DNA-hybrids.

o Peptide – DNA conjugation DNA-hybrids via thiol or amino linkage.

Design considerations

Some of the following considerations may be helpful when determining peptide design:

- A peptide with no charged or polar groups may be very insoluble. These amino acids decrease

solubility: – Trp, Val, Ile, Phe. These amino acids increase solubility: – Lys, His, Arg, Asp, Glu, Ser, Thr. - Proline breaks up beta sheet formations and although non-polar, helps to solubilise peptides.

- A spacer between a dye or tag and the rest of the peptide sequence can be advantageous.

- It is always more cost effective to put a dye or tag at the N-terminus rather than the C-terminus as this

can be incorporated during the standard synthesis. C-terminus additions require many more steps,

thus increasing the cost. - N-terminal glutamine (Gln) should be avoided. It is very unstable and rapidly forms the cyclic pyro

glutamic acid. It is best to add either pyroglutamic acid itself or include an acetyl group at the Nterminal glutamine. - Avoid regions containing long strings of valine or isoleucine as these are extremely difficult to

incorporate and may prevent any extension of the synthesis. - Multiple additions of phospho-amino acids can sometimes be difficult to incorporate during synthesis.

- Naturally cysteine occurs in proteins with a disulphide bridge, therefore we would advise to avoid

cysteine when designing peptides for raising antibodies.

Amino acid classification

The following table gives a general classification of the amino acids

| Class | Amino Acid |

|---|---|

| Acidic, polar | Asp, Glu Asn, |

| Basic, polar | His, Lys, Arg |

| Polar uncharged | Asn, Cys, Gly, Gln, Pro, Ser, Thr, Tyr |

| Nonpolar and hydrophobic | Ala, Ile, Leu, Met, Phe, Trp, Val |

Methodology

We use solid phase synthesis to synthesise peptides (SPPS, pioneered by Robert Bruce Merrifield). The process involves anchoring the C-terminal of the first amino acid to polystyrene-based resins and then, in a stepwise process, coupling the carboxyl group or C-terminus of the next amino acid to the amino group or N-terminus of another (peptide bond formation). Due to the possibility of unintended side-chain reactions,

protecting groups are used where applicable.

Our use of Fmoc chemistry enables greater flexibility in synthesis options. Chemical peptide synthesis starts at the C-terminal end of the peptide and ends at the N-terminus.

When the peptide chain is complete, it is cleaved from the resin with acid, a process that also removes the amino acid side chain protection. After removal of the acid, the peptide is ready for QC by HPLC and mass spectrometry before being freeze-dried, packaged and dispatched.

We are always keen to discuss a particular requirement for peptide synthesis. Future articles in this series will discuss peptide purity and analysis of the synthesised product, modifications and unnatural amino acids, specific options in making peptides for raising antibodies, as well as considerations on solubility and storage.

For further information, please contact us:

E: info@altabioscience.com

T: +44 (0)1527 584495

Author: Sat Sandhu, Principal Peptide Chemist.